Oil contamination is a major pollution issue that poses a risk to the environment along with industries. Indutrial discharge, oil leakage, and oil spills all contribute to oil pollution and water’s presence in oil can have detrimental effects both ecologically and operationally. Monitoring and detecting the oil content in water is crucial to minimizing these consequences. This is also essential to ensure the safety of people as well as regulatory compliance, and industrial use. This is the purpose of oil-in-water sensors.

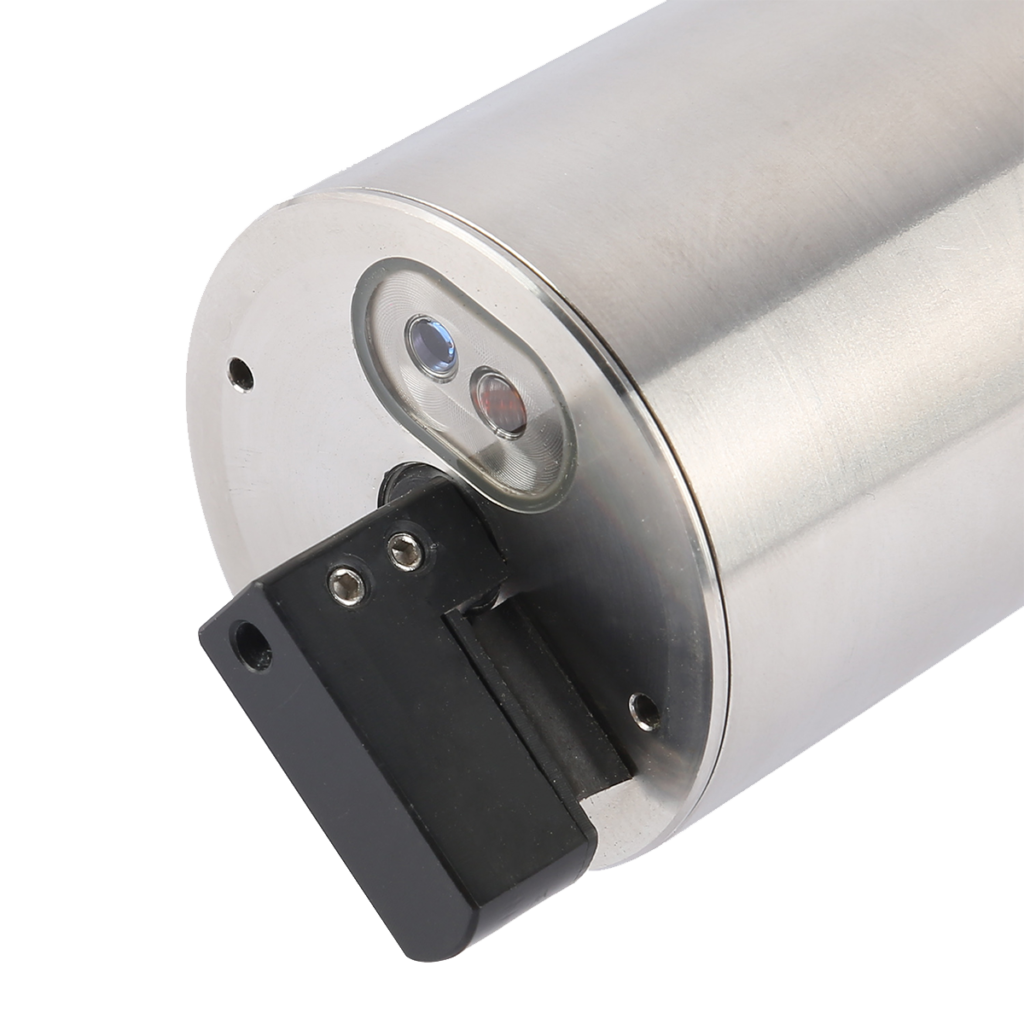

Instruments designed to measure levels of oil in water are called oil in water sensor, and they can be used in water bodies, industrial processes, and wastewater systems. These sensors rely on sophisticated technology to accurately and reliably quantify oil presence in real time. Because of their precision, they are crucial in several industries like oil and gas, wastewater management, and marine services.

Working Mechanism of Oil In Water Sensors

The sensors have different operating principles. They can be customized for different applications. Below are the most common types of detection technologies used in these sensors:

- Sensors of Fluorescence: Ultraviolet and Infrared (UVF) Sensors

These sensors use UV light to trigger an excitation in oil molecules causing them glow.

The intensity of light emitted is then counted to find out the oil concentration.

They are extremely sensitive, enabling detection of very small amounts of oil in water.

- Infrared Absorption (IR) Sensors

These sensors work by noting oil’s absorption of infrared (IR) light to determine the oil content.

Oil-containing materials are quantifiable by measuring the IR light absorption at certain wavelengths.

Suitable for detecting crude, refined petroleum products, as well as other hydrocarbon-based oils.

- Laser Induced Break Down Spectroscopy (LIBS)

A small quantity of H2O is subjected to high energy laser pulses which converts it to plasma.

The resultant light is analyzed for wavelength contamination of oil.

Highly accurate continuous monitoring is possible.

- Scatter And Turbidity Dawning Sensors

These sensors assess the amount of light scattered from the oil droplets dispersed in water.

Detection of oil-in-water emulsions are possible with these sensors.

These sensors are typically utilized in water treatment and monitoring of industrial waste effluents.

- Electrochemical Sensors

The sensors can determine oil pollution by monitoring change is conductivity or other associated electric chemical processes.

They are effective in situations where a chemical composition is needed to be determined.

Every sensor possesses unique pros and cons and the choice of sensor depends on the particular conditions of the application these technologies are going to be used on.

Uses of Oil in Water Sensors

Among the developed instruments for oil monitoring, sensors that measure the presence of oil contamination in water are the most common. They are used in:

- Environmental Monitoring

For oil and gas exploration and production, Oil and Gas companies use the services offered by the local government and various Environmental NGOs.

Improves proactive response to oil spill incidents and rectify damage caused to the contaminated waters ecosystems faster.

- Industrial Process Monitoring

Refineries, power stations, and other industrial enterprises use power equipment featuring these sensors to control the quality of effluents at wastewater treatment plants.

Fitness for the surrounding nature and guarantee the non-detrimental impact on natural water bodies.

- Offshore Oil and Gas Industry

The devices are installed at the fore submersible vertical pumps, responsible for the removal of produced water from oil wells, and at drilling rigs.

Handy in controlling the magnitude of environmental damage caused by storm water drainage from the offshore oil platforms.

- Wastewater Treatment Plants

The sensors aid in filtration of contaminated water such as oil before the water is discharged into the environment.

Maximizes improvement in separating oil from water.

- Marine and Shipping Industry

To ensure compliance with the International Convention on the Control of Harmful Anti-Fouling Systems on Ships, the devices are embedded within the boats.

Eliminate the discharge of oil bearing waste water to the seas.

- Food and Beverage Industry

In processing plants for food, used for the detection and control of oil waste residues in water effluents.

Ensures adherence to health and safety standards.

Advantages of Applying Oil in Water Sensors

The introduction of oil in water sensors is beneficial for industries as well as for environmental agencies. Some important benefits are:

- Real-Time Monitoring

Continuous oil pollution detection enables instant remediation measures to be implemented.

Decreases dependency on field sampling and subsequent testing in a laboratory.

- High Sensitivity and Accuracy

Advanced detection methods enable a minimum of a single drop of oil to be detected over a large area of water.

Improves the determination of oil concentration measurement.

- Cost Effective

Assists industries in bypassing expensive legal payments due to non-compliance.

Decreases cost incurred for oil spill response actions and remediation activity.

- Increased Safety and Greater Multidisciplinary Protection of the Environment

Minimizes environmental contamination from efficient spill and leakage detection.

Help conserve water and protect marine life for the future.

- Compliance With Restrictions

Certain industries are obligated to comply with specific environmental restrictions for oil discharges.

Oil in water sensors supplies the information required for regulatory compliance reporting and audits.

Difficulties and Prospective Directions

Despite the advancement brought by oil in water sensors for the detection and monitoring of oil, there are still challenges to address.

Interference by Other Elements: Detection procedures may face the challenge of interference from other organic materials found in water which can disrupt the measurement.

Sensor maintenance and calibration: Sensors require maintenance and calibrations throughout its operational years in order to maintain accuracy and prolong the lifespan.

Diversity of oil: Different types of oils, such as light and heavy crude, as well as refined oil products, may require custom detection methodologies.

Emerging Trends

Progress is being made in more sophisticated oil in water sensors. New developments include the following:

Incorporation into IoT and artificial intelligence systems: Advanced smart sensors with AI-enabled analysis for self-monitoring and predictive maintenance functions.

Reduction in Size: Sensors designed for remote monitoring and field work need to be made more compact and portable.

Increased sensitivity: Detection capability limits have been raised to allow the detection of even smaller parts per million of oil in water.

Hybrid Methods: More efficient and accurate oil monitoring would be achieved through the integration of multiple methodologies for detection.

Conclusion

At the end of the day, the oil in water sensors remain a crucial device to facilitate the measuring and control of oil contamination in water bodies. With advancement in sensor technology, both industries and environmental agencies are better equipped to manage oil pollution than they were ever able to. As the future unfolds, it is only optimistic to assume that industries will be able to achieve these goals with even greater precision, speed, and affordability. All these factors combined would play a crucial role in ensuring the quality of water and the protection of the environment. The new sensors will enable industries to ensure compliance, maximization of advantages, and hence, support a world that is less polluted.